Aluminium industry views tariffs and trade dispute with concern

German aluminium industry reports small increase in turnover in 2018. Expectations for 2018/19 cautiously optimistic.

Despite all the political uncertainty, sentiment in the German aluminium industry is characterized by cautious optimism. “Demand from industrial markets is at a satisfactory level,” said Christian Wellner, executive member of the managing board of GDA, the German aluminium association, at a press conference at ALUMINIUM 2018 in Düsseldorf. He added that in the first nine months of the year production by German aluminium companies had been driven by good demand from the automotive sector and had again showed a small increase. “Optimism continues to influence our expectations for growth, and the medium to long term outlook is also positive because global demand for aluminium is growing steadily. Even though the German market is already one of the largest markets for aluminium worldwide, it too will continue to grow further. As an industrial location, Germany offers the complete spectrum of activities covering production, processing and machining of aluminium.”

The German aluminium industry can look back on an eventful few months both in terms of what has been happening politically as well as in the marketplace. Business activity in the aluminium sector in Germany was good in the first half of 2018. Aluminium producers (+0.9%) and semis producers (+0.4%) both reported small increases in production in the first two quarters, while converters reported a small fall in production (-1.3%). In Düsseldorf, Christian Wellner made the current situation clear: “Economic risks for the second half of the year have increased significantly: trade disputes, punitive tariffs are having an adverse effect on developments. On top of this are the risks associated with the supply of raw materials as a result of the USA’s sanctions against Russia. We are viewing these developments with concern.”

Initially, the punitive tariffs of 10% imposed by the USA on certain aluminium products did not have a particularly marked effect on the sector. According to Christian Wellner, “about 82,000 tonnes of aluminium products made in Germany were exported to the USA in 2017. This represented 2% of total German production. Although this may not appear to be a large amount at first, one needs to remember that there are some export-intensive companies that deal with the USA and a considerably higher proportion of their production was affected.” The aluminium products involved here are of a high quality that is not produced in the USA. Local processors in the USA are reliant on these products and must pay the punitive tariffs. These tariffs give cause for concern because the American president has triggered or exacerbated trade disputes worldwide.

The USA’s sanctions against Russia have affected the Rusal group in particular. Rusal supplies the EU with 1.6 million tonnes of aluminium a year. It is the EU’s largest aluminium supplier and is also closely linked to Western partners along the whole chain, from procurement of raw materials through to the primary smelter. Amongst other things, Rusal operates an alumina plant at Aughinish in Ireland. The plant is Europe’s largest alumina producer. It supplies European primary smelters with the alumina they need as raw material for their own production. The plant is therefore an indispensable supplier of alumina to the European market. “If Aughinish is not able to supply alumina in the short to medium future, there is a danger of losses in production, plants being shut down and the need for a cost-intensive restart of smelters in Germany and the rest of Europe that will last for months,” explained Wellner.

He made it clear in his statement that the trade and tariffs dispute had shown how important it is for Germany to have an industrial base. This needs to be maintained by all means. “This applies to the whole value chain for our industry. Under no circumstances can we forego metal production in Germany. It is absolutely necessary to keep the remaining primary aluminium smelters that we have in Germany and we need to further strengthen recycling as an additional source of supply.”

Overall, Wellner said he could not see any fundamental economic downturn in the second half of the year but, given the increased uncertainty, he said on average he was only expecting a marginal increase in production for the sector. However, he was more optimistic where the future is concerned: “Electromobility, digitalization, sustainability and additive manufacturing are some of the megatrends that will boost the aluminium sector still further in the future.” The aluminium industry was well equipped to meet these challenges, he said. “We are developing and helping develop tomorrow’s products and solutions.” As a globally available and universally usable material with ever new possible applications, aluminium is a symbol of technical development in the 21st century.

![Fig. 1: Illustration of past and expected development of primary aluminium production. Historic values are from [3], extended by three development scenarios from [4]. Fig. 1: Illustration of past and expected development of primary aluminium production. Historic values are from [3], extended by three development scenarios from [4].](https://www.aluminium-journal.com/sites/default/files/styles/image_368_207/public/ww/2024-01/abb_rectifiers_alproduction_online.jpeg.webp?itok=AtRrgKQt)

Rectifiers and the aluminium industry developed conjointly, as increasing potline currents and voltage ratings of smelting plants require high power rectifiers.

In part II of this article we focus on the joint development, as increasing potline currents and voltage ratings of smelting plants require high power rectifiers.

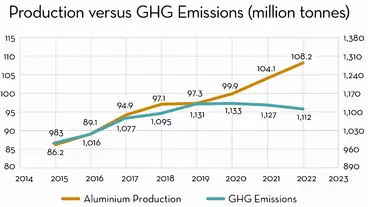

New data from the International Aluminium Institute (IAI) show that, for the first time, total greenhouse gas emissions from the global aluminium sector have not grown, even though aluminium production has shown an increase.