Ametek Land extends Spot Al EQS range

Ametek Land extends the measuring range of its Spot Al EQS pyrometer for even more aluminium applications.

Ametek Land, manufacturer of monitors and analysers for industrial infrared non-contact temperature measurement, has continued innovating its Spot Al EQS aluminium applications pyrometer by introducing two new modes for forging and forming applications.

Measuring range of Ametek's Spot Al EQS pyrometer is extended

The new F and F Mg (magnesium) algorithms extend Ametek Land’s capabilities to provide accurate, repeatable temperature measurements to additional aluminium production and processing industries. The new algorithms are suitable for reheating and secondary processing applications with thicker alloy-dependent oxide layers.

The new F and F Mg modes of Spot Al EQS are well suited to billet temperature measurements at the entry to the extrusion press or during other aluminium pre-heating processes. They provide the most accurate digital temperature readings of low and variable emissivity aluminium to ensure optimised process speed, process efficiency, and high-quality products with minimal scrap.

Continuous innovations

, explains: “We are continually innovating within our Spot Al EQS range, and this latest development is designed to ensure that our cutting-edge pyrometer can be utilised in an even wider range of aluminium applications. This latest development has been widely tested in conjunction with secondary aluminium producers and has proven highly effective. It significantly enhances the pyrometer’s scope and opens up new measurement opportunities.”

Five measurement modes

The Spot Al EQS pyrometer now offers five measurement modes, with dedicated pre-set algorithms that provide the most accurate digital temperature readings of low and variable emissivity aluminium. This ensures optimised press speed and high-quality products with minimal scrap.

Potential F and F Mg applications include:

- Billet profile

- Ingot/sales (re)heat furnace

- Pre-heating and forging

- Induction heating/heat treatment

- Mounting/shrinking

- Preheating for coating/bending

Spot Al EQS is an advanced non-contact infrared pyrometer providing a single sensor solution for aluminium extrusion, strip mill, forming/forging, and further processing.

A highly accurate and stable digital pyrometer, the Spot Al EQS uses Ametek Land’s cutting-edge Spot technology and unique, advanced data-processing algorithms to measure aluminium temperature at an extruder press exit; quench and billets; strip mill; forging/forming applications; and forging/forming applications with high-magnesium content alloys.

Offering measurements ranging from 200°C (392°F) to 700°C (1292 °F), the pyrometer integrates with control systems to optimise throughput at the press or mill.

Data is made immediately available via a rear display or via a web server. Video cameras within the pyrometer and remote access to all features enable the user to view, configure, and focus the pyrometer locally or remotely.

Combining Ethernet, Modbus TCP, video, analogue, and alarm outputs in a single device, the Spot Al EQS is designed specifically for measuring the temperature of aluminium in a range of processing applications.

Radar-based width measuring at the roughing stand leads to a more stable rolling process despite the harsh conditions with high occurrence of splashing water, steam and scale.

MiniTest FH from Elektrophysik reveals its strengths when it comes to measuring the wall thickness of aluminium foils, sheets or tubes.

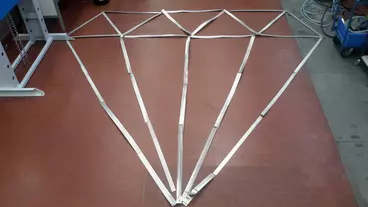

Diamond-coated tungsten-copper welding caps represent a promising approach for wear-free resistance spot welding of aluminium.