Automotive supplier SET orders laser blanking line from Schuler

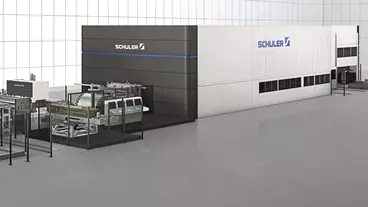

SET Enterprises has awarded Schuler the order for a highly versatile laser blanking line for its facility in Chicago, Illinois. The new line will be the first high-output system of its kind used in North America.

SET Enterprises based in Sterling Heights, Michigan, is a major supplier of blanks and slit multiples to the domestic automotive industry. Its list of customers includes several major automotive OEMs, Tier 1 stampers and large automotive producing sheet mills.

The laser blanking line with its combined laser power of 12 kilowatts will be used to produce blanks for exposed and unexposed automotive stampings beginning in 2019. The automotive supplier ultimately chose the laser blanking system because of its demonstrated high output capability and flexibility offered by the DynamicFlow Technology. This features three laser heads with the ability to simultaneously cut blank shapes of all types with straight line cutting speeds of over 100 m/min from a coil-fed, continuously forward-moving strip of coiled metal, itself travelling at speeds up to 60 m/min. This high output feeding and cutting capability makes conventional blanking dies unnecessary and, as a result, allows for optimization of blank shape and nesting optimization to achieve improved blanking yield and support formability.

Installation of the line will begin this summer, with the operational handover scheduled for the spring of next year. With this equipment in place a total of five Schuler laser blanking lines with three lasers will be in operation, producing class A blanks for the European and US-American automotive industry.

Feinguss Blank becomes ‘sustainable global force’ through investment by UK-based Texmo Precision Castings.

For passenger cars, automotive supplier Xin Peng forms high-quality parts made from steel and aluminium on new Schuler press line.

Russia’s aluminium producer Rusal has developed a new AlZn alloy for the automotive industry.