Omler launches new decoring machine on the market

The Italian company Omler srl has developed a new decoring machine, which is now launched on the market.

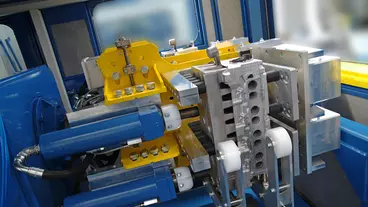

The decoring machine DCB18, now launched on the market, enables the simultaneous removal of sand cores from various cast iron, aluminium and steel castings

Omler is well known for its decoring solutions for the foundry industry, in particular for gravity, low pressure and lost wax foundries. In partnership with its qualified distributors and agents network, Omler sells its pneumatic decoring hammers RVC70 and AF1470 globally. Each hammer model is available in three different versions, according to the type of casting to decore. Furthermore, the company designs and manufactures the decoring benches in accordance with customer needs. Inside a decoring bench the decoring hammers are fastened in a fixed horizontal or vertical position, depending on the casting type to process. The position of the hammers is defined during the design phase, in consultation with the customer to determine the best decoring solution.

Decoring machine DCB18 with unique selling point launched on the market

In recent years Omler’s management, technical and sales staff have responded to customer and market demands and developed a new and more efficient decoring machine. This has resulted in the innovative rotating decoring machine DCB18, for which a patent is pending. The machine enables the simultaneous removal of sand cores from various cast iron, aluminium and steel castings. Each casting can weigh up to 70 kg, including sand.

Each DCB18-type decoring machine can decore up to four castings at the same time. The castings are processed by at least one pair of decoring hammers. The housings in which the castings are clamped are designed and manufactured depending on the casting dimensions.

Loading and unloading of the castings can be either manual or robot-assisted. A unique feature of the DCB18 machine is that it allows a rotary movement of up to 360 degrees in both directions of rotation without the decoring hammers having to interrupt their work. With this design, it is possible to process large batches of castings. And, of course, all Omler hammer models can be fastened in the DCB18 machine.

For safety reasons, the DCB18 is mounted in a soundproof cabin certified according to EN 1090-1:2009+A1:2011 and UNI EN ISO 11690-1. The cabin can be equipped with a container in which the sand is collected or with a conveyor belt that transports the sand out of the cabin.

Hindalco relies on modern technologies for the production of highly sensitive battery foil and orders foil rolling mills and foil slitting machines from Achenbach.

The machining of aluminium for components in electric vehicles is challenging. Innovative solutions and tools are required to meet the industry’s standards.

The demands for efficiency in production still remain high: high machining volumes must be achieved quickly, reliably and economically.